Whilst most people are familiar with the tactics employed during contract (re-)negotiation such as the ‘hard renegotiation’ (comply to my demands or risk losing the business) or ‘let’s create a partnership’, often responded to by suppliers with ‘increase my slice of the pie’, or ‘extend the duration of the contract so that I can give you a bigger discount’ (just a few examples), these are typically initiated and managed by the procurement/purchasing department as a one off item.

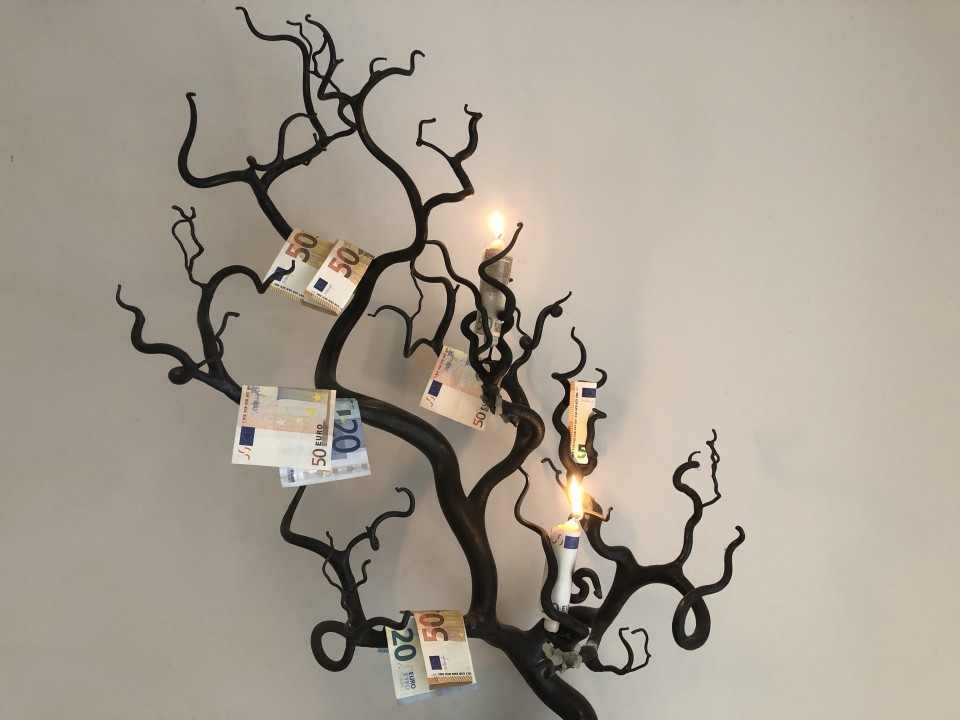

Unfortunately, if you’re dealing with a large outsourcing contract, those initial savings (if they ever existed and were not just pipe dreams) will soon be forgotten and new savings will be demanded. Since money doesn’t grow on trees, this is where post-award contract management has a difficult time in creating additional savings because the ‘deal’ has already been made. Nevertheless, contracts are made to be changed, so here are some suggestions based on my experience both as a solution manager (supplier side), consultant and having been responsible for contract management (customer side) of such large-scale outsourcing contracts.

- The obvious, ‘Eliminate waste’: whilst this should be done by default, it’s often overlooked and hidden due to the multi-department coverage of an outsourcing deal, whereby one department assumes that another is taking care. I have seen Items being paid for without validation simply because “they have always been on the bill”. Invoices can often be complex and monthly validation becomes just another tick-box on someone’s agenda, thereby losing attention. It can be worthwhile freeing up a resource or even hiring an external (not that I would dream of using this article to promote my own abilities J ) to occasionally scrutinize the invoice and ask the ‘stupid’ question…’what is this? And why are we paying it?’. Examples to consider are: Old tooling systems that may have been transformed but never decommissioned, temporary connectivity during transformations/migrations, data center floorspace that has not been reclaimed/returned, un-necessary reports that nobody is reading, or functions that have been automated (but for which the costs were people based), to name just a few.

- Revision of governance obligations: Suppliers typically spend ca. 6% of their cost base on governing outsourcing relationships. This includes account-, contract-, service-, finance managers and any supporting PMO’s/assistants etc., many of which tend to be international, incurring significant travel costs at the expense of the customer. At the same time, most customers find their governance meetings to be duplications, or re-iterations of previous meetings with little or no added value. Personally, many governance meetings that I attended had too many participants (many with nothing to say) or were unable to make decisions (one of the parties insisting that another governance body needed to make the call) and cost more than the decisions they were debating. Consider turning weekly meetings into bi-weekly or monthly meeting. Re-structuring the hierarchy of meetings to prevent duplication and restricting agenda items to a minimum all help to reduce effort and thereby cost. The most effective (and yet least adopted) potential reduction in governance effort is also to create a clear charter of responsibilities whereby decisions can truly be taken at the lowest possible level, thereby avoiding escalation through governance. A simple method for this is to set a financial level (similar to procurement approval levels) whereby topics need to be agreed upon (up to a specific maximum fee) within meeting/board X and may not be escalated to meeting/board Y. Some suppliers will insist on particular governance meetings in order to comply with internal regulations/rules, whilst the customer has little or no interest in the topics being raised. Such meetings should be simply transferred to a different approval medium such as email confirmation, letters/notification or sign-off forms. You will undoubtedly find that outsourcing creates uncertainty, causing people to mitigate the risk of losing control by insisting on a contact person. In extreme cases, this can cause interfaces to be created at all levels and in all geographies. Whilst potentially necessary during the initial transition to the outsourcing party, this kind of ‘governance’ tends to remain in place post-transition unless addressed, causing unexpected costs and potential claims for fees. Whilst applying the above may only save 1% of governance costs, remember that this will also free up internal resources to address more important topics.

- Billing complexity: Whether you have a consumption (Price*Quantity) based contract(s) or simply need to track project/professional services costs across many geographies, bills/invoices tend to be complex and at the same time limited in their content. Many line items with codes or summary descriptions often prevent sensible assessment of actual costs. Whilst some departments will give extra focus to validating their costs, others will simply approve the bill if it appears to be in line with expectations (often based simply on last month’s bill!). Having worked on the supplier side, don’t be surprised that the same is true from a cost perspective. Suppliers tend to use time tracking systems to generate invoices, assuming that internal staff have booked their hours to the right codes. These codes are often linked to internal budgets and it becomes all too easy for staff to lazily book their forgotten hours to the codes with large budgets (typically with less controls in place). Demanding that bills/invoices can be clearly linked to work which is evidenced will help to both reduce waste (item 1) and eliminate costs which may not be valid. Also reconsider what level of granularity is truly necessary for approval purposes. If it’s logical that 5 line-items are necessary for a product, then consolidate these as one item and reduce complexity, thereby reducing the chance of errors and the time needed for validation. In comparison, if you lease a car, you don’t expect a bill that details the maintenance costs, insurance or road tax because you know that these items are required.

- Reporting obligations: Upon initiating an outsourcing deal, the team dealing with the RFP will typically research the necessity of existing reports and combine this with best practices and the supplier’s list of standard reports, ultimately leading to an extensive set of obligatory reports which still don’t meet requirements upon contract signature (because requirements evolve) and somehow generating reports on topics which nobody feels responsible for. Obviously, a supplier tries to standardize to meet price expectations whilst their sales team believes that meeting the customer’s demands must be easy to do and tend to over-promise on what is available. Whilst some reports may be obligatory, depending upon the industry, most are there to provide evidence of SLA/KPI achievement or put concerns to rest regarding staffing, security and customer satisfaction. The ‘good’ suppliers have digitalized many reports, providing near real-time online reporting whilst other still generate manual reports which tend to run a week or two behind actual events. Ask yourself if these reports are truly useful and if they help to steer the situation. I have previously worked at a company where traffic light reports were abandoned in favor of focusing solely on the problem areas. Whilst this can appear to create a negative environment (you only hear about problems), it actually enabled people to focus on the real issues in the knowledge that everything else was running okay. Others that I have worked with want the reassurance that everything is okay and insist on such reports. The trick is to have a big enough stick to use to overcome the necessity of assurance. Clearly, if a supplier agrees to report only on issues and fails to do so, there needs to be some level of penalty applied for ‘hiding’ or failing to inform their customer. If this is a step too far, consider simply reducing frequency, content or changing the medium through which the report is to be provided.

- SLA/KPI adjustment: This is probably my favorite cost saving topic, simply because it has so many opportunities. Whether it’s reducing service windows, adjusting response times, decreasing availability, or one of many other possibilities, you will almost always find some level of SLA/KPI which can be tuned to reduce supplier efforts whilst having zero to minimal impact on the business. Many SLA’s/KPI’s are simply put into place as ‘insurance’ to satisfy a curious and concerned business, whilst forgetting that these same KPI’s need to be reported on. Also, without any contract change being needed, it’s essential to collaborate with whomever is responsible for architecture and technical transformation within your company to understand where and when resilience may be being introduced that can help to relax or at least utilize a lower cost service/KPI. Classical examples that I still come across today are those where customers have legacy business critical environments with limited technical resilience. The customer traditionally bought the ‘platinum’ service from their supplier to ensure a fast response if an incident occurs. As the business then migrates this environment to a multi-cloud environment or develops the application layer to provide inherent resilience, the KPI remains at the ‘platinum’ level whereas this could easily be reduced to the lowest level possible due to technological resilience.

- Risk reduction: A surprising amount of supplier fees is actually based on risk! If you’re a customer that has negotiated a contract in which you think that every eventuality is covered, then you’re probably paying a high-risk premium. Contractual sentences such as ‘software upgrades are included’, ‘annual benchmarking may be applied’ or ‘all travel expenses are included’ demonstrate that someone was good enough to consider the inclusion of these items into the contract, but that your supplier will have made a calculation on the chance of occurrence, potential cost and then increased this value with a risk margin. Placing a cap/maximum on such items or gaining transparency on costs before renegotiating them can help to reduce the risk and thereby reduce supplier fees. It’s also good to have a list of these ‘risk’ increasing items before going into a benchmark where the supplier will receive the benefit of taking these risks from the benchmarking party.

- Location of operations: I hear you thinking…but that’s why I outsourced…I don’t care where my supplier does it. The question is really, whether or not this works for your company. Leaving regulations and data privacy aside, there is sometimes a simple issue that your own off-/near- shoring activities don’t work well with those of your supplier(s). Whether its language barriers, time zones, or cultural issues, sometimes it simply doesn’t work effectively. This causes more effort internally and thereby higher costs. You may also be using the supplier’s offshore teams on projects, pushing up project costs with expensive internal travel costs. Suppliers will often have multiple delivery centers and although there will be costs involved in switching between them, this may very well reduce other costs that create a more effective relationship.

- Simplification and unification of tooling: Most suppliers will need to retain their toolsets to make their shared resource pools and software investments effective, meaning that they will not quickly adopt a customer’s tool landscape (unless at additional cost). Similarly, many customers will not abandon their tools for fear of losing information upon a supplier exit. This often leads to a duplication in toolsets (security, architecture, billing, CMDB, asset management, ticket logging, reporting, etc.) and the corresponding license fees, operations resources and supporting infrastructure. The ‘deal’ usually includes some level of automated gateway to link the tools for the important processes, but many sub-processes remain unaddressed. Depending upon the scale of outsourcing and retained organization, consider adopting the supplier toolset (consolidating), including additional contract amendments to reduce risk upon exit. If consolidation is not an option, at least review access requirements (licenses are often user based) to reduce the footprint of tools which are now largely redundant. The tooling landscape has also developed over the past years with many now having the ability to absorb the functionality of more niche/specialistic tools. Aggregating legacy tools into a new environment can often drive down licensing costs, making the change affordable. The new aggregated tool is then far easier to integrate with the supplier.

Of course, everyone should expect their supplier to come with the above items as proposals during their cycles of continuous improvement and I have seen some suppliers doing this to a limited extent. Unfortunately, some motivation from the customer perspective is often required.

Great information. Luckily for me, I found your site. I made a bookmark for later! How do we communicate?

Hi friend! I constanly needed to write on my website something like that. Can i include a fragment of your post to my website ?